Library of models of technological devices

| Name: | TechApp |

| Founded: | october 2005 |

| Version: | 1.0.0 |

| State: | Free (GPL) |

| Author: | Roman Savochenko, Maxim Lysenko (2007,2010), Ksenia Yashina (2007) |

| Description: | Provides the library of models of technological devices. |

| Address: | DB in file: SQLite.LibDB.techApp ( |

About the library

The library is created to provide the models of devices of technological processes. The library is not static, but based on the module JavaLikeCalc, allowing to create calculations on the Java-like language.

To address the functions of the library you can use static call address "DAQ.JavaLikeCalc.lib_techApp.{Func}()" or dynamic "SYS.DAQ.JavaLikeCalc["lib_techApp"]["{Func}"].call()", "SYS.DAQ.JavaLikeCalc["lib_techApp"].{Func}()". Where {Func} — function identifier in the library.

To connect the library to the project of the OpenSCADA station it is possible by downloading the attached file of the database, placing it in in the database directory of the station's project and creating the database object for the DB module "SQLite", indicating the database file in the configuration.

For each function it was evaluated the execution time. Measurements were made on the system with the following parameters: Athlon 64 3000 + (2000MGts) + ALTLinux 5.1, 32bit by measuring the total execution time of the function when you call it 1000 times. Selection was made for the smallest value of the five computations. Time is in angle brackets and is measured in microseconds.

1 Conception

The basis of the model of each unit is the calculation of the input flow and output pressure based on the input pressure and output flow. In general, models of technological devices are described by difference equations for discrete machines.

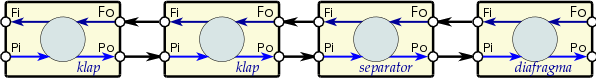

Based on the functions of this library you can easily and quickly build models of technological processes in the module BlockCalc by combining the blocks in accordance with the technological scheme. Example of combination of several devices of the technological scheme is shown in Fig. 1.

Fig. 1. An example of the block scheme of the technological process.

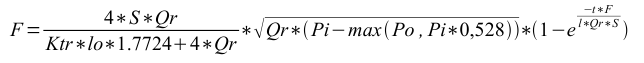

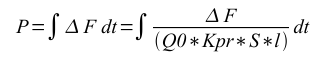

The basis of the model of any technological device are two basic formulas, namely the formula of flow and pressure. The canonical formula of the flow computation for the pipe section, or restriction of flow area is given by (1).

S — section (m2).

Qr — real density of the medium (kg/m3).

∆P — pressure drop (at).

The actual density is calculated by the formula (2).

Kpr — coefficient of compressibility of the medium (0,001 — liquid; 0,95 — gas).

Pi — input pressure (at).

Each tube makes the dynamic resistance to the flow associated with the friction of the pipe walls and that depends on the flow velocity. The dynamic resistance of the pipe is expressed by (3). The total flow of the medium, taking into account the dynamic resistance is calculated by formula (4).

Kr — coefficient of friction of the walls of the pipe.

D — diameter of the pipeline (m).

l — pipeline length (m).

v — flow velocity in the pipeline (m3/hour).

Equation (1) describes the laminar outflow of medium to critical velocities. In the case of exceeding the critical flow velocity the calculation is made by the formula (5). A universal formula for calculating the flow at all speeds will have the formula (6).

In dynamical systems the change of the flow at the end of the pipe does not change instantaneously, but lags behind the time travel of the medium plot from the beginning of the pipeline to its end. The time depends on the length of the pipe and velocity of the medium in the pipe. Delay of the flow changing at the end of the pipe can be described by formula (7). The resulting formula for calculating of the the flow in the pipe, taking into account the above features, written in the form (8).

t — time.

v — velocity of the flow = F/(Qr*S).

(8)

(8)The pressure of the medium in the volume is usually calculated identically for all cases by formula (9).

(9)

(9)2 The library structure

The library contains about two dozen of models of the often needed technological processes devices and supporting elements. The functions' names and its parameters are available in three languages: English, Russian and Ukrainian.

Lag (lag) <1.2>

Description: Lag model. You can use this for sensors' variables lag imitation.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| out | Output | Real | Return | false | 0 |

| in | Input | Real | Input | false | 0 |

| t_lg | Lag time (s) | Real | Input | false | 10 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 100 |

Program:

Noise (2 harmonic + rand) (noise) <3.5>

Description: Noise model. Contain three parts:

- first harmonic part;

- second harmonic part;

- noise based on randomize generator of numbers.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| out | Output | Real | Return | false | 0 |

| off | Main offset | Real | Input | false | 1 |

| a_g1 | Harmonic part 1 amplitude | Real | Input | false | 10 |

| per_g1 | Harmonic part 1 period (s) | Real | Input | false | 10 |

| a_g2 | Harmonic part 2 amplitude | Real | Input | false | 5 |

| per_g2 | Harmonic part 2 period (s) | Real | Input | false | 0.1 |

| a_rnd | Random numbers amplitude | Real | Input | false | 1 |

| f_frq | Calc function period (Hz) | Real | Input | true | 100 |

| tmp_g1 | Harmonic part 1 counter | Real | Input | true | 0 |

| tmp_g2 | Harmonic part 2 counter | Real | Input | true | 0 |

Program:

Ball crane (ballCrane) <1.4>

Description: Ball crane model. Include going and estrangement time.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| pos | Position (%) | Real | Output | false | 0 |

| com | Command | Boolean | Input | false | 0 |

| st_open | State "Open" | Boolean | Output | false | 0 |

| st_close | State "Close" | Boolean | Output | false | 1 |

| t_full | Going time (s) | Real | Input | false | 5 |

| t_up | Estrangement time (s) | Real | Input | false | 0.5 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 100 |

| tmp_up | Estrangement counter | Real | Input | true | 0 |

| lst_com | Last command | Boolean | Input | true | 0 |

Program:

Separator (separator) <14>

Description: Separator model included two phase: liquid and gas.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow (tones/h) | Real | Output | false | 0 |

| Pi | Input pressure (ata) | Real | Input | false | 1 |

| Si | Input cutset (m2) | Real | Input | false | 0.2 |

| Fo | Output flow (tones/h) | Real | Input | false | 0 |

| Po | Output pressure (ata) | Real | Output | false | 1 |

| So | Output cutset (m2) | Real | Input | false | 0.2 |

| lo | Output length (m) | Real | Input | false | 10 |

| Fo_æ | Output liquid flow (tones/h) | Real | Input | false | 0 |

| Po_æ | Output liquid pressure (ata) | Real | Output | false | 1 |

| Læ | Liquid level (%) | Real | Output | false | 0 |

| ProcÆ | % liquid. | Real | Input | false | 0.01 |

| Vap | Device capacity (m3) | Real | Input | false | 10 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Qæ | Liquid density (kg/m3) | Real | Input | false | 1000 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 200 |

Program:

Valve (klap) <19.5>

Description: Valve model, include:

- two valve in one;

- super-critical speed;

- temperature change on baffling;

- work to one side, back valve;

- valve position speed control;

- nonlinear cut changing by open position.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow (tones/h) | Real | Output | false | 0 |

| Pi | Input pressure (ata) | Real | Input | false | 1 |

| Ti | Input temperature (K) | Real | Input | false | 273 |

| Fo | Output flow (tones/h) | Real | Input | false | 0 |

| Po | Output pressure (ata) | Real | Output | false | 1 |

| To | Output temperature (K) | Real | Output | false | 273 |

| So | Output pipe cutset (m2) | Real | Input | false | .2 |

| lo | Output pipe length (m) | Real | Input | false | 10 |

| S_kl1 | Valve 1 cutset (m2) | Real | Input | false | .1 |

| l_kl1 | Valve 1 open (%) | Real | Input | false | 0 |

| t_kl1 | Valve 1 open time (s) | Real | Input | false | 10 |

| S_kl2 | Valve 2 cutset (m2) | Real | Input | false | .05 |

| l_kl2 | Valve 2 open (%) | Real | Input | false | 0 |

| t_kl2 | Valve 2 open time (s) | Real | Input | false | 5 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kln | Linearity coefficient | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| Ct | Warm capacity of environs | Real | Input | false | 20 |

| Riz | Warm resistance of isolation | Real | Input | false | 20 |

| noBack | Back valve | Boolean | Input | false | 0 |

| Fwind | Air speed | Real | Input | false | 1 |

| Twind | Air temperature | Real | Input | false | 273 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 200 |

| tmp_l1 | Position 1 lag | Real | Output | true | 0 |

| tmp_l2 | Position 2 lag | Real | Output | true | 0 |

Program:

Lag (clear) (lagClean) <2.9>

Description: Model of clear lag (transportable). Provide fir include some simple lag chains. Appointed for lags into long pipes.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| out | Output | Real | Return | false | 0 |

| in | Input | Real | Input | false | 0 |

| t_lg | Lag time (s) | Real | Input | false | 10 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 100 |

| cl1 | Chain 1 | Real | Input | true | 0 |

| cl2 | Chain 2 | Real | Input | true | 0 |

| cl3 | Chain 3 | Real | Input | true | 0 |

Program:

Boiler: barrel (boilerBarrel) <30.5>

Description: The model of the boiler's barrel.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi1 | Input water flow (tones/h) | Real | Output | false | 22 |

| Pi1 | Input water pressure (at) | Real | Input | false | 43 |

| Ti1 | Input water temperature (K) | Real | Input | false | 523 |

| Si1 | Input water cutset (m2) | Real | Input | false | 0.6 |

| Fi2 | Input smoke gas flow (tones/h) | Real | Output | false | |

| Pi2 | Input smoke gas pressure (at) | Real | Input | false | 1.3 |

| Ti2 | Input smoke gas temperature (K) | Real | Input | false | 1700 |

| Si2 | Input smoke gas cutset (m2) | Real | Input | false | 10 |

| Vi1 | Barrel volume (m3) | Real | Input | false | 3 |

| Lo | Barrel level (%) | Real | Output | false | 10 |

| S | Heated surface (ì2) | Real | Input | false | 15 |

| k | Heat transfer coefficient | Real | Input | false | 0.8 |

| Fo | Output steam flow (tones/h) | Real | Input | false | 20 |

| Po1 | Output steam pressure (at) | Real | Output | false | 41.68 |

| To1 | Output steam temperature (K) | Real | Output | false | 10 |

| So1 | Output steam pipe cutset (m2) | Real | Input | false | 0.5 |

| lo1 | Output steam pipe length (m) | Real | Input | false | 5 |

| Fo2 | Output smoke gas flow (tones/h) | Real | Input | false | 180 |

| Po2 | Output smoke gas pressure (at) | Real | Output | false | 1 |

| To2 | Output smoke gas temperature (K) | Real | Input | false | 0 |

| Fpara | Inner barrel steam flow (tones/h) | Real | Output | false | 0 |

| Tv | Inner water temperature (K) | Real | Output | false | 0 |

| f_frq | Calc frequency (Hz) | Real | Input | false | 200 |

Program:

Boiler: burner (boilerBurner) <50.5>

Description: The fire chamber's of the boiler model which works with three fuels: blast-furnace gas, coke and natural gas.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi1 | Input blast furnace gas flow (tone/h) | Real | Output | false | |

| Pi1 | Input blast furnace gas pressure (at) | Real | Input | false | |

| Ti1 | Input blast furnace gas temperature (K) | Real | Input | false | 40 |

| Si1 | Input blast furnace gas pipe cutset (m2) | Real | Input | false | |

| Fi2 | Input natural gas flow (tone/h) | Real | Output | false | |

| Pi2 | Input natural gas pressure (at) | Real | Input | false | |

| Ti2 | Input natural gas temperature (K) | Real | Input | false | 20 |

| Si2 | Input natural gas pipe cutset (m2) | Real | Input | false | |

| Fi3 | Input coke oven gas flow (tone/h) | Real | Output | false | |

| Pi3 | Input coke oven gas pressure (at) | Real | Input | false | |

| Ti3 | Input coke oven gas temperature (K) | Real | Input | false | 0 |

| Si3 | Input coke oven gas pipe cutset (m2) | Real | Input | false | |

| Fi4 | Input air flow (tone/h) | Real | Output | false | |

| Pi4 | Input air pressure (at) | Real | Input | false | |

| Ti4 | Input air temperature (K) | Real | Input | false | 20 |

| Si4 | Input air cutset (m2) | Real | Input | false | |

| Fo | Output smoke gas flow (tones/h) | Real | Input | false | |

| Po | Output smoke gas pressure (at) | Real | Output | false | |

| To | Output smoke gas temperature (K) | Real | Output | false | |

| So | Output smoke gas pipe cutset (m2) | Real | Input | false | 90 |

| lo | Output smoke gas pipe length (m) | Real | Input | false | |

| V | Burner volume (m3) | Real | Input | false | 830 |

| CO | The percentage of CO in the flue stack gases (%) | Real | Output | false | |

| O2 | The percentage of O2 in the flue stack gases (%) | Real | Output | false | |

| f_frq | Calc frequency (Hz) | Real | Input | false | 200 |

Program:

Network (loading) (net) <13>

Description: Loading with constant pressure on network. Contain parameter for noise connection.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow (tones/h) | Real | Output | false | 10 |

| Pi | Input pressure (ata) | Real | Input | false | 1 |

| Po | Output pressure setpoint (ata) | Real | Input | false | 1 |

| So | Output pipe cutset (m2) | Real | Input | false | 0.1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| Noise | Input flow's noise | Real | Input | false | 1 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 200 |

Program:

Source (pressure) (src_press) <12>

Description: Source pressure with constant pressure. Contained the parameter for noise connection.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Pi | Input pressure setpoint (at) | Real | Input | false | 10 |

| Fo | Output flow (tones/h) | Real | Input | false | 0 |

| Po | Output pressure (at) | Real | Output | false | 1 |

| So | Output pipe cutset (m2) | Real | Input | false | 0.1 |

| lo | Output pipe length (m) | Real | Input | false | 100 |

| Noise | Input flow's noise | Real | Input | false | 1 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 200 |

| Fit | Input flow laged | Real | Output | true | 0 |

Program:

Air cooler (cooler) <16.5>

Description: Model of the air cooler for gas flow.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow (tones/h) | Real | Output | false | 0 |

| Pi | Input pressure (at) | Real | Input | false | 1 |

| Ti | Input temperature (K) | Real | Input | false | 273 |

| Si | Cooler's pipes cutset (m2) | Real | Input | false | 0.05 |

| li | Full cooler's pipes length (m) | Real | Input | false | 10 |

| Fo | Output flow (tones/h) | Real | Input | false | 0 |

| Po | Output pressure (at) | Real | Output | false | 1 |

| To | Output temperature (K) | Real | Output | false | 273 |

| So | Output pipe cutset (m2) | Real | Input | false | .2 |

| lo | Output pipe length (m) | Real | Input | false | 10 |

| Tair | Cooling air temperature (Ê) | Real | Input | false | 283 |

| Wc | Cooler performance | Real | Input | false | 200 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Ct | Warm capacity of environs | Real | Input | false | 100 |

| Rt | Warm resistance of isolation | Real | Input | false | 1 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 200 |

Program:

Gas compressor (compressor) <12>

Description: Model of the gas compressor. Implement surge effect. Sarge count from the dynamic-gas curve, and next count coefficient of sarge margin.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow (tones/h) | Real | Output | false | 0 |

| Pi | Input pressure (at) | Real | Input | false | 1 |

| Ti | Input temperature (K) | Real | Input | false | 273 |

| Fo | Output flow (tones/h) | Real | Input | false | 0 |

| Po | Output pressure (at) | Real | Output | false | 1 |

| To | Output temperature (K) | Real | Output | false | 273 |

| So | Output pipe cutset (m2) | Real | Input | false | 0.2 |

| lo | Output pipe length (m) | Real | Input | false | 2 |

| Kzp | Surge protect margin coefficient | Real | Output | false | 0.1 |

| N | Turnovers (1000 x turn/min) | Real | Input | false | 0 |

| V | Capacity (m3) | Real | Input | false | 7 |

| Kpmp | Surge coefficient (surge point) | Real | Input | false | 0.066 |

| Kslp | Slope coefficient of surge curve | Real | Input | false | 0.08 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| Ct | Warm capacity of environs | Real | Input | false | 100 |

| Riz | Warm resistance of isolation | Real | Input | false | 100 |

| Fwind | Air speed | Real | Input | false | 1 |

| Twind | Air temperature | Real | Input | false | 273 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 200 |

| Fit | Input flow laged | Real | Output | true | 0 |

Program:

Source (flow) (src_flow) <2.2>

Description: Source of constant flow. Contained parameter for noise connection.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow setpoint (tones/h) | Real | Input | false | 10 |

| Fo | Output flow (tones/h) | Real | Input | false | 10 |

| Po | Output pressure (at) | Real | Output | false | 1 |

| So | Output pipe cutset (m2) | Real | Input | false | 0.1 |

| lo | Output pipe length (m) | Real | Input | false | 100 |

| Noise | Input flow's noise | Real | Input | false | 1 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 100 |

Program:

Pipe-base (pipeBase) <11.5>

Description: Implementation of the basic foundations of the model pipe:

- Flow in the pipe, taking into account the speed, pressure drop, resistance due to friction and the critical flow.

- Calculation of pressure.

- Accounting for medium density and degree of compressibility for both gases and liquids.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow (tones/h) | Real | Output | false | 0 |

| Pi | Input pressure (at) | Real | Input | false | 1 |

| Ti | Input temperature (K) | Real | Input | false | 293 |

| Si | Input cutset (m2) | Real | Input | false | .2 |

| Fo | Output flow (tones/h) | Real | Input | false | 0 |

| Po | Output pressure (at) | Real | Output | false | 1 |

| To | Output temperature (K) | Real | Output | false | 293 |

| So | Output cutset (m2) | Real | Input | false | .2 |

| lo | Output length (m) | Real | Input | false | 10 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.98 |

| Ktr | Coefficient of friction | Real | Input | false | 0.01 |

| f_frq | Calc frequency (Hz) | Real | Input | false | 100 |

Program:

Pipe 1->1 (pipe1_1) <36.5>

Description: Model of the pipe by scheme: 1 -> 1.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow (tones/h) | Real | Output | false | 0 |

| Pi | Input pressure (at) | Real | Input | false | 1 |

| Fo | Output flow (tones/h) | Real | Input | false | 0 |

| Po | Output pressure (at) | Real | Output | false | 1 |

| So | Output cutset (m2) | Real | Input | false | .2 |

| lo | Output length (m) | Real | Input | false | 10 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 200 |

| Pti | Pti | Real | Output | true | 1 |

| Fto | Fto | Real | Output | true | 0 |

| Pt1 | Pt1 | Real | Output | true | 1 |

| Ft1 | Ft1 | Real | Output | true | 0 |

Program:

Pipe 2->1 (pipe2_1) <26>

Description: Model of the pipe by scheme: 2 -> 1.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi1 | Input 1 flow (tones/h) | Real | Output | false | 0 |

| Pi1 | Input 1 pressure (at) | Real | Input | false | 1 |

| Ti1 | Input 1 temperature (K) | Real | Input | false | 273 |

| Si1 | Input 1 cutset (m2) | Real | Input | false | 0.2 |

| Fi2 | Input 2 flow (tones/h) | Real | Output | false | 0 |

| Pi2 | Input 2 pressure (at) | Real | Input | false | 1 |

| Ti2 | Input 2 temperature (K) | Real | Input | false | 273 |

| Si2 | Input 2 cutset (m2) | Real | Input | false | 0.2 |

| Fo | Output flow (tones/h) | Real | Input | false | 0 |

| Po | Output pressure (at) | Real | Output | false | 1 |

| To | Output temperature (K) | Real | Output | false | 273 |

| So | Output cutset (m2) | Real | Input | false | .2 |

| lo | Output length (m) | Real | Input | false | 10 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| Ct | Warm capacity of environs | Real | Input | false | 20 |

| Riz | Warm resistance of isolation | Real | Input | false | 20 |

| Fwind | Air speed | Real | Input | false | 1 |

| Twind | Air temperature (Ê) | Real | Input | false | 273 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 100 |

Program:

Pipe 3->1 (pipe3_1) <36>

Description: Model of the pipe by scheme: 3 -> 1.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi1 | Input 1 flow (tones/h) | Real | Output | false | 0 |

| Pi1 | Input 1 pressure (at) | Real | Input | false | 1 |

| Ti1 | Input 1 temperature (K) | Real | Input | false | 273 |

| Si1 | Input 1 cutset (m2) | Real | Input | false | 0.2 |

| Fi2 | Input 2 flow (tones/h) | Real | Output | false | 0 |

| Pi2 | Input 2 pressure (at) | Real | Input | false | 1 |

| Ti2 | Input 2 temperature (K) | Real | Input | false | 273 |

| Si2 | Input 2 cutset (m2) | Real | Input | false | 0.2 |

| Fi3 | Input 3 flow (tones/h) | Real | Output | false | 0 |

| Pi3 | Input 3 pressure (at) | Real | Input | false | 1 |

| Ti3 | Input 3 temperature (K) | Real | Input | false | 273 |

| Si3 | Input 3 cutset (m2) | Real | Input | false | 0.2 |

| Fo | Output flow (tones/h) | Real | Input | false | 0 |

| Po | Output pressure (at) | Real | Output | false | 1 |

| To | Output temperature (K) | Real | Output | false | 273 |

| So | Output cutset (m2) | Real | Input | false | .2 |

| lo | Output length (m) | Real | Input | false | 10 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| Ct | Warm capacity of environs | Real | Input | false | 20 |

| Riz | Warm resistance of isolation | Real | Input | false | 20 |

| Fwind | Air speed | Real | Input | false | 1 |

| Twind | Air temperature (Ê) | Real | Input | false | 273 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 100 |

Program:

Pipe 1->2 (pipe1_2) <25.5>

Description: Model of the pipe by scheme: 1 -> 2.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow (tones/h) | Real | Output | false | 0 |

| Pi | Input pressure (at) | Real | Input | false | 1 |

| Fo1 | Output 1 flow (tones/h) | Real | Input | false | 0 |

| Po1 | Output 1 pressure (at) | Real | Output | false | 1 |

| So1 | Output 1 cutset (m2) | Real | Input | false | .2 |

| lo1 | Output 1 length (m) | Real | Input | false | 10 |

| Fo2 | Output 2 flow (tones/h) | Real | Input | false | 0 |

| Po2 | Output 2 pressure (at) | Real | Output | false | 1 |

| So2 | Output 2 cutset (m2) | Real | Input | false | .2 |

| lo2 | Output 2 length (m) | Real | Input | false | 10 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 100 |

| F1tmp | Temporary flow 1 | Real | Output | true | 0 |

| F2tmp | Temporary flow 2 | Real | Output | true | 0 |

| Pot1 | Temporary pressure 1 | Real | Output | true | 1 |

| Pot2 | Temporary pressure 2 | Real | Output | true | 1 |

Program:

Pipe 1->3 (pipe1_3) <36.5>

Description: Model of the pipe by scheme: 1 -> 3.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow (tones/h) | Real | Output | false | 0 |

| Pi | Input pressure (at) | Real | Input | false | 1 |

| Fo1 | Output 1 flow (tones/h) | Real | Input | false | 0 |

| Po1 | Output 1 pressure (at) | Real | Output | false | 1 |

| So1 | Output 1 cutset (m2) | Real | Input | false | .2 |

| lo1 | Output 1 length (m) | Real | Input | false | 10 |

| Fo2 | Output 2 flow (tones/h) | Real | Input | false | 0 |

| Po2 | Output 2 pressure (at) | Real | Output | false | 1 |

| So2 | Output 2 cutset (m2) | Real | Input | false | .2 |

| lo2 | Output 2 length (m) | Real | Input | false | 10 |

| Fo3 | Output 3 flow (tones/h) | Real | Input | false | 0 |

| Po3 | Output 3 pressure (at) | Real | Output | false | 1 |

| So3 | Output 3 cutset (m2) | Real | Input | false | .2 |

| lo3 | Output 3 length (m) | Real | Input | false | 10 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 100 |

| F1tmp | Temporary flow 1 | Real | Output | true | 0 |

| F2tmp | Temporary flow 2 | Real | Output | true | 0 |

| F3tmp | Temporary flow 3 | Real | Output | true | 0 |

| Pot1 | Temporary pressure 1 | Real | Output | true | 1 |

| Pot2 | Temporary pressure 2 | Real | Output | true | 1 |

| Pot3 | Temporary pressure 3 | Real | Output | true | 1 |

Program:

Pipe 1->4 (pipe1_4) <47.5>

Description: Model of the pipe by scheme: 1 -> 4.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow (tones/h) | Real | Output | false | 0 |

| Pi | Input pressure (at) | Real | Input | false | 1 |

| Fo1 | Output 1 flow (tones/h) | Real | Input | false | 0 |

| Po1 | Output 1 pressure (at) | Real | Output | false | 1 |

| So1 | Output 1 cutset (m2) | Real | Input | false | .2 |

| lo1 | Output 1 length (m) | Real | Input | false | 10 |

| Fo2 | Output 2 flow (tones/h) | Real | Input | false | 0 |

| Po2 | Output 2 pressure (at) | Real | Output | false | 1 |

| So2 | Output 2 cutset (m2) | Real | Input | false | .2 |

| lo2 | Output 2 length (m) | Real | Input | false | 10 |

| Fo3 | Output 3 flow (tones/h) | Real | Input | false | 0 |

| Po3 | Output 3 pressure (at) | Real | Output | false | 1 |

| So3 | Output 3 cutset (m2) | Real | Input | false | .2 |

| lo3 | Output 3 length (m) | Real | Input | false | 10 |

| Fo4 | Output 4 flow (tones/h) | Real | Input | false | 0 |

| Po4 | Output 4 pressure (at) | Real | Output | false | 1 |

| So4 | Output 4 cutset (m2) | Real | Input | false | .2 |

| lo4 | Output 4 length (m) | Real | Input | false | 10 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 100 |

| F1tmp | Temporary flow 1 | Real | Output | true | 0 |

| F2tmp | Temporary flow 2 | Real | Output | true | 0 |

| F3tmp | Temporary flow 3 | Real | Output | true | 0 |

| F4tmp | Temporary flow 4 | Real | Output | true | 0 |

| Pot1 | Temporary pressure 1 | Real | Output | true | 1 |

| Pot2 | Temporary pressure 2 | Real | Output | true | 1 |

| Pot3 | Temporary pressure 3 | Real | Output | true | 1 |

| Pot4 | Temporary pressure 4 | Real | Output | true | 1 |

Program:

Valve proc. mechanism (klapMech) <3>

Description: Model of the valve process mechanism. Include going time (aperiodic chain of two level) and estrangement time.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| pos | Position (%) | Real | Output | false | 0 |

| pos_sensor | Position by sensor (%) | Real | Output | false | 0 |

| com | Command | Real | Input | false | 0 |

| st_open | State "Open" | Boolean | Output | false | 0 |

| st_close | State "Close" | Boolean | Output | false | 1 |

| t_full | Going time (s) | Real | Input | false | 3 |

| t_up | Estrangement time (s) | Real | Input | false | 1 |

| t_sensor | Sensors' lag time (s) | Real | Input | false | 1 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 100 |

| tmp_up | Estrangement count | Real | Output | false | 0 |

| lst_com | Last command | Real | Output | false | 0 |

Program:

Diaphragm (diafragma) <14>

Description: Diaphragm model.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi | Input flow (tones/h) | Real | Output | false | 0 |

| Pi | Input pressure (at) | Real | Input | false | 1 |

| Fo | Output flow (tones/h) | Real | Input | false | 0 |

| Po | Output pressure (at) | Real | Output | false | 1 |

| dP | Pressure differential (kPa) | Real | Output | false | 0 |

| Sdf | Diaphragm cutset (m2) | Real | Input | false | 0.1 |

| So | Output pipe cutset (m2) | Real | Input | false | 0.2 |

| lo | Output pipe length (m) | Real | Input | false | 10 |

| Q0 | Norm density of environs (kg/m3) | Real | Input | false | 1 |

| Kpr | Compressibility coefficient (0...1) | Real | Input | false | 0.95 |

| f_frq | Calc frequency (Hz) | Real | Input | true | 100 |

Program:

Heat exchanger (heatExch) <28.4>

Description: The model of the heat exchanger, it calculates the heat exchange of the two streams.

Parameters:

| ID | Parameter | Type | Mode | Hide | Default |

| Fi1 | Input 1 flow (tones/h) | Real | Input | false | 20 |

| Pi1 | Input 1 pressure (at) | Real | Input | false | 1 |

| Ti1 | Input 1 temperature (K) | Real | Input | false | 20 |

| Si1 | Input 1 cutset (m2) | Real | Input | false | 1 |

| li1 | Input 1 length (m) | Real | Input | false | 10 |

| Q0i1 | Input 1 norm density (kg/m3) | Real | Input | false | 1 |

| Kpr1 | Input 1 compressibility coefficient (0...1) | Real | Input | false | 0.9 |

| Ci1 | Input 1 warm capacity | Real | Input | false | 1 |

| Fi2 | Input 2 flow (tones/h) | Real | Input | false | 20 |

| Pi2 | Input 2 pressure (at) | Real | Input | false | 1 |

| Ti2 | Input 2 temperature (K) | Real | Input | false | 40 |

| Si2 | Input 2 cutset (m2) | Real | Input | false | 1 |

| li2 | Input 2 length (m) | Real | Input | false | 10 |

| Q0i2 | Input 2 norm density (kg/m3) | Real | Input | false | 1 |

| Kpr2 | Input 2 compressibility coefficient (0...1) | Real | Input | false | 0.9 |

| Ci2 | Input 2 warm capacity | Real | Input | false | 1 |

| ki | Heat transfer coefficient | Real | Input | false | 0.9 |

| Fo1 | Output 1 flow (tones/h) | Real | Input | false | 0 |

| Po1 | Output 1 pressure (at) | Real | Output | false | 1 |

| To1 | Output 1 temperature (K) | Real | Output | false | 273 |

| So1 | Output 1 cutset (m2) | Real | Output | false | 1 |

| lo1 | Output 1 length (m) | Real | Output | false | 10 |

| Fo2 | Output 2 flow (tones/h) | Real | Input | false | 0 |

| Po2 | Output 2 pressure (at) | Real | Output | false | 1 |

| To2 | Output 2 temperature (K) | Real | Output | false | 273 |

| So2 | Output 2 cutset (m2) | Real | Output | false | 1 |

| lo2 | Output 2 length (m) | Real | Output | false | 10 |

| f_frq | Calc frequency (Hz) | Real | Input | false | 200 |

Program:

Ññûëêè