User protocol based library

| Name: | UserPrtDevs |

| Founded: | January 2010 |

| Version: | 1.8 |

| State: | Free (GPL2 by default) |

| Author: | Roman Savochenko |

| Description: | Library of functions for provide access to data of different network devices with most simply protocols like to wide resources counters. |

| Address: | DB in file: SQLite.LibDB.tmplib_DevLib and SQLite.LibDB.UserProtocol_uPrt ( |

| Compatibility: | OpenSCADA >= 0.9 |

About the library

The templates library "DevLib" is created to provide common templates and related functions for custom access to wide range of devices' data with simple protocol to implement into User Protocol module, present complex protocols (ModBus, OPC_UA, HTTP) or direct at internal language and also for some integration the devices data.The template's names and it's parameters are available in languages: English, Ukrainian and Russian. Source code wrote into language independent mode with calls for the translations by function tr() and the message's translation also allowed for English, Ukrainian and Russian.

To connect the library to the project of the OpenSCADA station it is possible by downloading the attached file of the database, placing it in in the database directory of the station's project and creating the database object for the DB module "SQLite", indicating the database file in the configuration.

To use the templates at generic you need create the device representing object into module of Logical controller and select proper template from the templates library. Next follow to specific for the template into individual description to correct configuration.

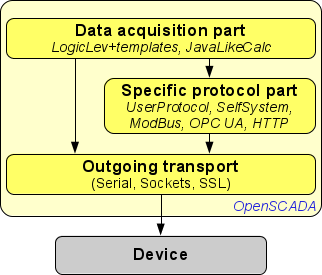

In general the custom accessing conception to the device's data we can imagine like to figure 1.

Fig.1. Custom accessing to device's data conception.

As you can see from image 1 intermediate to the device carried out through some transport by the device physical base. Requests to the transport you can send:

- Directly by OpenSCADA system API function of the transport object string messIO( string mess, real timeOut = 0 );, if the protocol specific part very simple and you need only the data extract.

- Wrapped data request req by function int messIO( XMLNodeObj req, string prt ); and for protocol prt, if the protocol part complex enough and already present into OpenSCADA.

- Specific for custom wrapped data request by function int messIO( XMLNodeObj req, "UserProtocol" ); and user protocol implementation, if the protocol part complex enough and not yet present into OpenSCADA. Here user implement self the protocol specific part into UserProtocol module and the data specific part into the template for module Logical controller or direct into controller's procedure of the internal language module JavaLikeCalc.

For placing here a protocol you need do next and follow to shown demands:

- be the copyright holder or the author of the code and distribute it's under any free license, GPL preferred;

- prepare and store the code into a separated DB file of SQLite or as a text file includes all the function's attributes description and the procedure's source text, which was wrote and formed in some system way;

- write a short description and instruction for connect a device by the protocol in way like to the other ones here;

- write the direct request to placing the protocol here to the forum topic "

OpenSCADA development" includes a proving of it's ability to work from any OpenSCADA developer or a short demonstration video.

OpenSCADA development" includes a proving of it's ability to work from any OpenSCADA developer or a short demonstration video.

1. SMS (SMS)

Description: Provides operations with SMS by the GSM-modem connected as a serial device. For now supported only sending SMS messages to a number of remote cell phone or GSM modem. For sending supported: ECHO disable, PIN check and set, send in PDU and Text mode.Author: Roman Savochenko <

Version: 2.1

Output user protocol's XML request structure: <{cmd} pin="1111" tel="+380XXXXXXXXX" text="{0|1}" err="1:Error">{SMSText}</cmd>

cmd — command, for now only "send" allowed;

pin — PIN code to the SIM card access;

tel — telephone number for receiver (remote cell phone or GSM modem);

text{0,1} — SMS in the text mode, only ASCII

SMSText — the message text;

err — sets for the request result.

Using/configuring:pin — PIN code to the SIM card access;

tel — telephone number for receiver (remote cell phone or GSM modem);

text{0,1} — SMS in the text mode, only ASCII

SMSText — the message text;

err — sets for the request result.

- Create an output transport type "Serial" and set ID that like "SMS", one transport allowed for more receivers.

- Set proper address, only for Serial device. The serial port speed, asynchronous data format and timeouts will adjusted by the function.

- Place some commands requests direct to present or new internal OpenSCADA procedures like:

- Result: Into variable rez you will get "OK" if no errors occur and the messages transmitted to the receiver.

2. SMTP (SMTP)

Description: Provides operations with EMail by its send through TCP-Socket or SSL. For now supported: TCP, SSL, AUTH, topic encoding for UTF-8.Author: Roman Savochenko <

Version: 1.1

Output user protocol's XML request structure: <send auth="{user}:{pass}" from="{FromAddr}" to="{ToAddr}" topic="{My Topic}" err="1:Error">{MessageText}</send>

topic — the message topic;

from — sender address;

to — destination address of the receiver;

auth — authenticate user and password;

MessageText — the message text;

err — sets for the request result.

Using/configuring:from — sender address;

to — destination address of the receiver;

auth — authenticate user and password;

MessageText — the message text;

err — sets for the request result.

- Create an output transport type "Sockets" or "SSL" and set ID that like "SMTP", one transport allowed for more receivers.

- Set proper address, for Sockets(25) or SSL(465). The transport's timeouts will adjusted by the function.

- Place some commands requests direct to present or new internal OpenSCADA procedures like:

- Result: Into variable rez you will get "OK" if no errors occur and the messages transmitted to the receiver.

3. UPS (UPS)

Description: Uninterruptible power supply unifying data for provide all the data into single attribute of object type "All items" for next the control as the object with the data provide as table, alarming and allowing set writable attributes. The template aimed for using with module "System" data source as "UPS" and widget "Main.objProps" as the data presenter. The template also you can use as example for create like other data unification as complex object with properties, alarming and writing.Author: Roman Savochenko <

Version: 1.2

Template parameters:

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| srcAddr | Source object's address | String | Input | Not attribute | Constant | |

| items | All items | Object | Output | Full access | Variable | |

| this | The object | Object | Input | Not attribute | Variable | |

| SHIFR | Code | String | Input | Not attribute | Variable | |

| NAME | Name | String | Input | Not attribute | Variable | |

| DESCR | Description | String | Input | Not attribute | Variable |

- Create a controller object into module "System" and set ID that like "SYSData".

- Create a parameter object into previous new the controller object and set ID that like "UPS".

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each the devices. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Source object's address — to address the UPS parameter object like "System.SYSData.UPS".

- Result: Into attribute items you will get the object with all attributes and its properties. At some violations into attribute "err" you will get the information.

- Into visual interfaces developing of Vision place widget "Main.objProps" to any page and link it to the parameter object crated into stage 4.

- Result: Into runtime the page you get table with data of the object, notifications about violations into the header and allowing for set writable properties.

4. Elemer TM510x (TM510x)

Description: Multichannels thermometer Elemer TM5102 and TM5103 of firmAuthor: Roman Savochenko <

Version: 1.0

Output user protocol's XML request structure: <mess addr="1" err="1:Error">{req}</mess>

req — request/respond data;

addr — remote station address (1...254);

err — sets for the request result.

Template parameters:addr — remote station address (1...254);

err — sets for the request result.

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport | String | Input | Not attribute | Constant | tm510x |

| addr | Device address (1...254) | Integer | Input | Not attribute | Constant | 1 |

| devTp | Device type | Integer | Input | Read only | Variable | |

| errors | Errors | String | Input | Read only | Variable | |

| in1 | Input 1 | Real | Input | Read only | Variable | |

| in2 | Input 2 | Real | Input | Read only | Variable | |

| in3 | Input 3 | Real | Input | Read only | Variable | |

| in4 | Input 4 | Real | Input | Read only | Variable | |

| in5 | Input 5 | Real | Input | Read only | Variable | |

| in6 | Input 6 | Real | Input | Read only | Variable | |

| in7 | Input 7 | Real | Input | Read only | Variable | |

| in8 | Input 8 | Real | Input | Read only | Variable |

- Create an output transport type "Serial" and set ID that like "tm510", one for each the devices' used serial bus.

- Set proper the address and the timeouts to the Serial device.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each the devices. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Transport — to ID of the transport into stage 1.

- Device address — to the device's logical address in bus by upper transport.

- Result: The logical parameter object will perform interaction and place gathered data to the parameter attributes.

5. EDWARDS TURBOMOLECULAR PUMPS (SCU750)

Description: Typical EDWARDS TURBOMOLECULAR PUMPS (Author: Roman Savochenko <

Sponsored: Vasiliy Grigoriev from "Vacuum technologies laboratory (

Version: 1.0

Output user protocol's XML request structure: <mess addr="1" err="1:Error">{req}</mess>

req — request/respond data;

addr — remote station address (<0 - single; >=0 - multi port);

err — sets for the request result.

Template parameters:addr — remote station address (<0 - single; >=0 - multi port);

err — sets for the request result.

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport | String | Input | Not attribute | Constant | SCU750 |

| addr | Device address (-1...255) | Integer | Input | Not attribute | Constant | 1 |

| perGet | Period data getting (s) | Real | Input | Not attribute | Constant | 10 |

| version | Version | String | Input | Read only | Variable | |

| snCntrUnit | Serial number: Control Unit | String | Input | Read only | Variable | |

| snPump | Serial number: Pump | String | Input | Read only | Variable | |

| cntPumpHour | Pump hour counter (minutes) | Real | Input | Read only | Variable | |

| cntCntrUnitHour | Control unit hour counter (minutes) | Real | Input | Read only | Variable | |

| cntStart | Start counter | Real | Input | Read only | Variable | |

| operMode | Pump Operation Mode | String | Input | Read only | Variable | |

| errors | Errors | String | Input | Read only | Variable | |

| events | Events | String | Input | Read only | Variable | |

| tTMS | TMS temperature (°Ñ) | Integer | Input | Read only | Variable | |

| tMotor | Motor temperature (°Ñ) | Integer | Input | Read only | Variable | |

| rotSpeed | Rotational speed (HZ) | Integer | Input | Read only | Variable | |

| comStart | Command: START | Boolean | Input | Full access | Variable | |

| comStop | Command: STOP | Boolean | Input | Full access | Variable | |

| comReset | Command: RESET | Boolean | Input | Full access | Variable | |

| spSpeed | Set point: Speed | Integer | Input | Full access | Variable | |

| spTMSt | Set point: TMS temperature | Integer | Input | Read only | Variable | |

| spSpeedPrev | Set point: Speed (previous) | Integer | Output | Not attribute | Variable | |

| cnt | Counter | Integer | Output | Not attribute | Variable | |

| operModes | Operation modes | Object | Output | Not attribute | Variable |

- Create an output transport type "Serial" and set ID that like "SCU750", one for each the devices' used serial bus.

- Set proper the address and the timeouts to the Serial device.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each the devices. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Transport — to ID of the transport into stage 1.

- Device address — to the device's logical address in bus by upper transport.

- Period data getting — to need acquisition period which more to real processing by the logical level controller. Commands and some other will process immediate.

- Result: The logical parameter object will perform interaction and place gathered data to the parameter attributes. Also you allowed for send some commands to the device through writable attributes.

6. Heat counter computer VKT7 (VKT7)

Description: Firm "Teplocom" (Author: Roman Savochenko <

Sponsored: Vladislav Chubuk

Version: 1.0

Output user protocol's XML request structure: <mess addr="1" err="1:Error">{req}</mess>

req — request/respond data;

addr — remote station address (0...254);

err — sets for the request result.

Template parameters:addr — remote station address (0...254);

err — sets for the request result.

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| imit | Imitation drift % (0-disable) | Real | Input | Not attribute | Constant | 0 |

| trAddr | Transport | String | Input | Not attribute | Constant | Transport.Serial.out_VKT7 |

| arhH | Archiver: hours | String | Input | Not attribute | Constant | |

| arhD | Archiver: days | String | Input | Not attribute | Constant | |

| arhRes | Archiver: results-month | String | Input | Not attribute | Constant | |

| maxDayDepth | Archiver: maximum read depth for no hours archiver, days | Integer | Input | Not attribute | Constant | 366 |

| lastResTm | Last result months read time (s) | Integer | Output | Full access | Variable | 0 |

| leftResTm | Left result months for read from archive | Integer | Output | Read only | Variable | |

| lastDTm | Last days read time (s) | Integer | Output | Full access | Variable | 0 |

| leftDTm | Left days for read from archive | Integer | Output | Read only | Variable | |

| lastHTm | Last hours read time (s) | Integer | Output | Full access | Variable | |

| leftHTm | Left hours for read from archive | Integer | Output | Read only | Variable | |

| diffTm | Difference time (server-counter), hours | Integer | Input | Read only | Variable | |

| firmVer | Firmware version | Real | Input | Read only | Variable | |

| abonId | Subscriber ID | String | Input | Read only | Variable | |

| repDay | Report day | Integer | Input | Read only | Variable | |

| netNum | Network number | Integer | Input | Read only | Variable | |

| modelImpl | Model implementation | Integer | Input | Read only | Variable | |

| tTypeM | t: dimension | String | Input | Read only | Variable | |

| GTypeM | G: dimension | String | Input | Read only | Variable | |

| VTypeM | V: dimension | String | Input | Read only | Variable | |

| MTypeM | M: dimension | String | Input | Read only | Variable | |

| PTypeM | P: dimension | String | Input | Read only | Variable | |

| QoTypeM | Qo: dimension | String | Input | Read only | Variable | |

| QntTypeHIM | ÂÍÐ: dimension | String | Input | Read only | Variable | |

| QntTypeM | ÂÎÊ: dimension | String | Input | Read only | Variable | |

| t1_1 | t1 (Tâ1) | Real | Input | Full access | Variable | |

| t2_1 | t2 (Tâ1) | Real | Input | Full access | Variable | |

| t3_1 | t3 (Tâ1) | Real | Input | Full access | Variable | |

| V1_1 | V1 (Tâ1) | Real | Input | Full access | Variable | |

| V2_1 | V2 (Tâ1) | Real | Input | Full access | Variable | |

| V3_1 | V3 (Tâ1) | Real | Input | Full access | Variable | |

| M1_1 | M1 (Tâ1) | Real | Input | Full access | Variable | |

| M2_1 | M2 (Tâ1) | Real | Input | Full access | Variable | |

| M3_1 | M3 (Tâ1) | Real | Input | Full access | Variable | |

| P1_1 | P1 (Tâ1) | Real | Input | Full access | Variable | |

| P2_1 | P2 (Tâ1) | Real | Input | Full access | Variable | |

| Mg_1 | Mg (Tâ1) | Real | Input | Full access | Variable | |

| Qo_1 | Qo (Tâ1) | Real | Input | Full access | Variable | |

| Qg_1 | Qg (Tâ1) | Real | Input | Full access | Variable | |

| dt_1 | dt (Tâ1) | Real | Input | Full access | Variable | |

| BNR_1 | ÂÍÐ (Tâ1) | Real | Input | Full access | Variable | |

| BOC_1 | ÂÎÑ (Tâ1) | Real | Input | Full access | Variable | |

| G1_1 | G1 (Tâ1) | Real | Input | Full access | Variable | |

| G2_1 | G2 (Tâ1) | Real | Input | Full access | Variable | |

| t1_2 | t1 (Tâ2) | Real | Input | Full access | Variable | |

| t2_2 | t2 (Tâ2) | Real | Input | Full access | Variable | |

| t3_2 | t3 (Tâ2) | Real | Input | Full access | Variable | |

| V1_2 | V1 (Tâ2) | Real | Input | Full access | Variable | |

| V2_2 | V2 (Tâ2) | Real | Input | Full access | Variable | |

| V3_2 | V3 (Tâ2) | Real | Input | Full access | Variable | |

| M1_2 | M1 (Tâ2) | Real | Input | Full access | Variable | |

| M2_2 | M2 (Tâ2) | Real | Input | Full access | Variable | |

| M3_2 | M3 (Tâ2) | Real | Input | Full access | Variable | |

| P1_2 | P1 (Tâ2) | Real | Input | Full access | Variable | |

| P2_2 | P2 (Tâ2) | Real | Input | Full access | Variable | |

| Mg_2 | Mg (Tâ2) | Real | Input | Full access | Variable | |

| Qo_2 | Qo (Tâ2) | Real | Input | Full access | Variable | |

| Qg_2 | Qg (Tâ2) | Real | Input | Full access | Variable | |

| dt_2 | dt (Tâ2) | Real | Input | Full access | Variable | |

| BNR_2 | ÂÍÐ (Tâ2) | Real | Input | Full access | Variable | |

| BOC_2 | ÂÎÑ (Tâ2) | Real | Input | Full access | Variable | |

| G1_2 | G1 (Tâ2) | Real | Input | Full access | Variable | |

| G2_2 | G2 (Tâ2) | Real | Input | Full access | Variable |

- Create an output transport type "Serial" and set ID that like "VKT7", one for each the devices.

- Set proper the address and the timeouts to the Serial device.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each the devices. Enable the parameter.

- Create or use a minutes (current) value archivator object (1m, period=60sek.).

- Create a hours value archivator object (arhH, period=3600sek.), days value archivator object (arhD, 86400sek.) and result month value archivator object (arhM, 86400sek.). Set "Period archiving (sec)" property of the archivators to '0' for disable the data flow from the archive buffer.

- Into tab "Template configuration" of the logical parameter object you need set:

- Imitation drift % — to '0' for the imitation disable.

- Transport — to path of the transport into stage 1, like "Transport.Serial.out_VKT7".

- Archiver: hours — to the hours archiver into stage 6, like "FSArch.arhH".

- Archiver: days — to the days archiver into stage 6, like "FSArch.arhD".

- Archiver: results-month — to the result month archiver into stage 6, like "FSArch.arhM".

- Archiver: maximum read depth for no hours archiver, days — to need for read no hours archives depth, in days.

- Into tab "Archiving" set archiving for needs attributes to the archivators.

- Result: The logical parameter object will perform interaction and place current gathered data to the parameter attributes and current archive. Other archives' data will read parallel from previous set depth by one value for period i.e. one day for minute period for days up to the current and last value.

7. Sycon Multi Drop Protocol (SMDP)

Description: STM devices for resonant frequency measurement for mass of deposited films attached to its surface by Sycon Instruments, Inc. (Author: Roman Savochenko <

Sponsored: Vasiliy Grigoriev from "Vacuum technologies laboratory (

Version: 1.0

Output user protocol's XML request structure: <mess addr="16" try="1" err="1:Error">{req}</mess>

req — request/respond data;

addr — remote device address [16...254];

try — tries for the request;

err — sets for the request result.

Template parameters:addr — remote device address [16...254];

try — tries for the request;

err — sets for the request result.

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport | String | Input | Not attribute | Constant | SMDP |

| addr | Device address (16...254) | Integer | Input | Not attribute | Constant | 16 |

| perGet | Period data getting (s) | Real | Input | Not attribute | Constant | 10 |

| version | Firmware Version | String | Input | Read only | Variable | |

| CfgPrmSSID | Configuration parameter session ID | Integer | Input | Read only | Variable | |

| Srlno | Measurement serial number | Integer | Input | Read only | Variable | |

| RawFreq | Channel freq. | Real | Input | Read only | Variable | |

| GoodFreq | Last used, good channel freq. (Hz) | Real | Input | Read only | Variable | |

| RawThick | Computed raw thickness, from frequency. (A) | Real | Input | Read only | Variable | |

| XtalThick | Computed material related thickness, can be zeroed. (A) | Real | Input | Read only | Variable | |

| XtalThick_F | Filtered computed material related thickness, can be zeroed. (A) | Real | Input | Read only | Variable | |

| XtalRate | Rate, angstroms per second. | Real | Input | Read only | Variable | |

| XtalRate_F | Rate, angstroms per second, filtered. | Real | Input | Read only | Variable | |

| XtalLife | XtalLife (%) | Real | Input | Read only | Variable | |

| XtalQual | Quality level (0-9). | Integer | Input | Read only | Variable | |

| XtalQualPeak | Highest quality level seen (0-9). | Integer | Input | Read only | Variable | |

| XtalStab | Stability level (0-9). | Integer | Input | Read only | Variable | |

| XtalStabPeak | Highest stability level seen (0-9). | Integer | Input | Read only | Variable | |

| XtalStat | Channel status. | String | Input | Read only | Variable | |

| XtalLife_C | XtalLife (%). | Integer | Input | Read only | Variable | |

| SessId | Session ID | Integer | Input | Full access | Variable | |

| Fq | Xtal start freq. (Hz) | Real | Input | Full access | Variable | |

| Fm | Xtal min freq. (Hz) | Real | Input | Full access | Variable | |

| Density | Material density (gm/cc). | Real | Input | Full access | Variable | |

| Zratio | Material Z ratio. Not scaled or unitized. | Real | Input | Full access | Variable | |

| Tooling | 1.000 is 100 % tooling (unity). | Real | Input | Full access | Variable | |

| RateReq | Requested rate (A/S). | Real | Input | Full access | Variable | |

| QlvlTrip | Quality threshold, if non 0 and exceeded, xtal fail occurs. | Integer | Input | Full access | Variable | |

| SlvlTrip | Stability threshold, if non 0 and exceeded, xtal fail occurs. | Integer | Input | Full access | Variable |

- Create an output transport type "Serial" and set ID that like "SMDP", one for each the devices' used serial bus.

- Set proper the address and the timeouts to the Serial device.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each the devices. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Transport — to ID of the transport into stage 1.

- Device address — to the device's logical address in bus by upper transport.

- Period data getting — to need acquisition period which more to real processing by the logical level controller. Commands and some other will process immediate.

- Result: The logical parameter object will perform interaction and place gathered data to the parameter attributes. Also you allowed for send some commands to the device through writable attributes.

8. Power supply for turbomolecular pumps (TMH)

Description: Power supply for turbomolecular pumps of firmAuthor: Roman Savochenko <

Sponsored: Vasiliy Grigoriev from "Vacuum technologies laboratory (

Version: 1.0

Output user protocol's XML request structure: <mess addr="1" err="1:Error">{req}</mess>

req — request/respond data;

addr — remote station address (1...32);

err — sets for the request result.

Template parameters:addr — remote station address (1...32);

err — sets for the request result.

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport | String | Input | Not attribute | Constant | TMP |

| addr | Device address (-1...255) | Integer | Input | Not attribute | Constant | 1 |

| perGet | Period data getting (s) | Real | Input | Not attribute | Constant | 10 |

| modelID | Model ID | String | Input | Read only | Variable | |

| errors | Errors | String | Input | Read only | Variable | |

| rotSpeed | Rotational speed (HZ) | Integer | Input | Read only | Variable | |

| I | Current (A) | Real | Input | Read only | Variable | |

| axle1disb | Axle 1 disbalance | Integer | Input | Read only | Variable | |

| axle2disb | Axle 2 disbalance | Integer | Input | Read only | Variable | |

| MP_X1 | MP X1 | Integer | Input | Read only | Variable | |

| MP_Y1 | MP Y1 | Integer | Input | Read only | Variable | |

| MP_X2 | MP X2 | Integer | Input | Read only | Variable | |

| MP_Y2 | MP Y2 | Integer | Input | Read only | Variable | |

| MP_Z | MP Z | Integer | Input | Read only | Variable | |

| operMode | Operation Mode | String | Input | Read only | Variable | |

| comStart | Command: START | Boolean | Input | Full access | Variable | |

| comStop | Command: STOP | Boolean | Input | Full access | Variable | |

| comReset | Command: RESET | Boolean | Input | Full access | Variable | |

| operCntr | Operation Control Mode | String | Input | Read only | Variable | |

| comInteract | Interactive mode | Boolean | Input | Full access | Variable | |

| comAutonom | Autonomous mode | Boolean | Input | Full access | Variable | |

| cnt | Counter | Integer | Output | Not attribute | Variable | |

| operModes | Operation modes | Object | Output | Not attribute | Variable |

- Create an output transport type "Serial" and set ID that like "TMP", one for each the devices' used serial bus.

- Set proper the address and the timeouts to the Serial device.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each the devices. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Transport — to ID of the transport into stage 1.

- Device address — to the device's logical address in bus by upper transport.

- Period data getting — to need acquisition period which more to real processing by the logical level controller. Commands and some other will process immediate.

- Result: The logical parameter object will perform interaction and place gathered data to the parameter attributes. Also you allowed for send some commands to the device through writable attributes.

9. Temperature measurement IT-3 (IT3)

Description: Temperature measurement IT-3 fromAuthor: Roman Savochenko <

Sponsored: Vasiliy Grigoriev from "Vacuum technologies laboratory (

Version: 1.2

Output user protocol's XML request structure: <mess addr="1" err="1:Error">{req}</mess>

req — request/respond data;

addr — remote station address (1...32);

err — sets for the request result.

Template parameters:addr — remote station address (1...32);

err — sets for the request result.

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport | String | Input | Not attribute | Constant | IT3 |

| addr | Device address | Integer | Input | Not attribute | Constant | 1 |

| T | Temperature | Real | Input | Read only | Variable | |

| H | Upper border | Boolean | Input | Read only | Variable | |

| L | Lower border | Boolean | Input | Read only | Variable | |

| relSt | Relay state | Boolean | Input | Read only | Variable |

- Create an output transport type "Serial" and set ID that like "IT3", one for each the devices' used serial bus.

- Set proper the address and the timeouts to the Serial device, typical "{serDevPath}:4800:8N2".

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each the devices. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Transport — to ID of the transport into stage 1.

- Device address — to the device's logical address in bus by upper transport.

- Result: The logical parameter object will perform interaction and place gathered data to the parameter attributes.

10. IVE-452HS-02 (IVE_452HS_02)

Description: Power supply of beam-electrons evaporator of "Plasma Tech" Ltd, from Moskov.Author: Roman Savochenko <

Sponsored: Vasiliy Grigoriev from "Vacuum technologies laboratory (

Version: 1.0

Output user protocol's XML request structure: <mess addr="255" err="1:Error">{req}</mess>

req — request/respond data;

addr — remote station address (0...255);

err — sets for the request result.

Template parameters:addr — remote station address (0...255);

err — sets for the request result.

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport | String | Input | Not attribute | Constant | Sockets.out_IVE |

| addr | Device address | Integer | Input | Not attribute | Constant | 255 |

| COIA | Output current level set-point | Integer | Output | Full access | Variable | |

| COUA | Output voltage level set-point | Integer | Output | Full access | Variable | |

| COPA | Output power level set-point | Integer | Output | Full access | Variable | |

| DIA | Output current | Integer | Input | Read only | Variable | |

| DUA | Output voltage | Integer | Input | Read only | Variable | |

| DPA | Output power | Integer | Input | Read only | Variable | |

| DFA | Electric arcs frequency | Integer | Input | Read only | Variable | |

| DAC | Electric arcs counter | Integer | Input | Read only | Variable | |

| COM_DEW | Command: Blocking by SC and XX | Boolean | Input | Full access | Variable | |

| COM_OUT | Command: Display on UI out block's params | Boolean | Input | Full access | Variable | |

| COM_DEP | Command: Enable MK | Boolean | Input | Full access | Variable | |

| COM_DEL | Command: Blocks #1,2 to net | Boolean | Input | Full access | Variable | |

| COM_UF | Command: Display on UI frequency and current | Boolean | Input | Full access | Variable | |

| DKW | MUBR of the block overheated | Boolean | Input | Read only | Variable | |

| DKZ | Short circuits on the block out | Boolean | Input | Read only | Variable | |

| DK | MK of the block overheated | Boolean | Input | Read only | Variable | |

| DE | Power and voltage on out present | Boolean | Input | Read only | Variable |

- Create an output transport type "Serial" direct, or by the Sockets gate and, set address that like "Sockets.out_IVE", one for each the devices' used serial bus.

- Set proper the address and the timeouts to the Serial device.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each the devices. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Transport — to the address of the transport into stage 1. Supported tracing for the hot change.

- Device address — to the device's logical address in bus by upper transport. Supported tracing for the hot change and real the device's address changing.

- Result: The logical parameter object will perform interaction and place gathered data to the parameter attributes. Also you allowed for send some commands to the device through writable attributes.

11. OPTRIS CT/CTL (OPTRIS)

Description: OPTRIS CT/CTL communication interface of "Optris" GmbH, from Berlin.Author: Roman Savochenko <

Sponsored: Vasiliy Grigoriev from "Vacuum technologies laboratory (

Version: 1.0

Output user protocol's XML request structure: <mess addr="1" cs="1" err="1:Error">{req}</mess>

req — request/respond data;

addr — remote station address (0...15);

ñs — use control sum for SET commands [0,1];

err — sets for the request result.

Template parameters:addr — remote station address (0...15);

ñs — use control sum for SET commands [0,1];

err — sets for the request result.

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport | String | Input | Not attribute | Constant | Serial.out_OPTRIS |

| addr | Device address | Integer | Input | Not attribute | Constant | 1 |

| Tproc | T process | Real | Input | Read only | Variable | |

| Thead | T head | Real | Input | Read only | Variable | |

| Tbox | T box | Real | Input | Read only | Variable | |

| Tact | T act. | Real | Input | Read only | Variable | |

| eps | IR epsilon | Real | Input | Full access | Variable | |

| trans | IR transmission | Real | Input | Full access | Variable | |

| spIll | Spot illumination | Logical | Input | Full access | Variable |

- Create an output transport type "Serial" direct, or by the Sockets gate and, set address that like "Serial.out_OPTRIS", one for each the devices' used serial bus.

- Set proper the address and the timeouts to the Serial device.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each the devices. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Transport — to the address of the transport into stage 1. Supported tracing for the hot change.

- Device address — to the device's logical address in bus by upper transport.

- Result: The logical parameter object will perform interaction and place gathered data to the parameter attributes. Also you allowed for send some commands to the device through writable attributes.

12. CTR 100, 101 (CTR)

Description: The RS232C Serial Interface permits the communication between the digital Oerlikon Leybold Vacuum CERAVAC, from Köln.Author: Roman Savochenko <

Sponsored: Vasiliy Grigoriev from "Vacuum technologies laboratory (

Version: 1.0

Output user protocol's XML request structure: <mess err="1:Error">{req}</mess>

req — request/respond data;

err — sets for the request result.

Template parameters:err — sets for the request result.

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport | String | Input | Not attribute | Constant | Serial.out_CTR |

| press | Pressure, Tor | Real | Output | Read only | Variable | |

| zeroSet | Zero set | Logical | Input | Full access | Variable |

- Create an output transport type "Serial" direct, or by the Sockets gate and, set address that like "Serial.out_CTR", one for each the devices' used serial bus.

- Set proper the address and the timeouts to the Serial device.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each the devices. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Transport — to the address of the transport into stage 1. Supported tracing for the hot change.

- Result: The logical parameter object will perform interaction and place gathered data to the parameter attributes. Also you allowed for send some commands to the device through writable attributes.

13. IEC-60870 (IEC60870)

Description:Version: 1.0

Author: Roman Savochenko <

Sponsored: Ustijancev Michael.

Implementing task:

Template parameters:

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport | String | Input | Not attribute | Constant | Sockets.out_IEC60870 |

| addr | Address, {addr}.{OA} | String | Input | Not attribute | Constant | 0.5 |

| tmRetr | Retry connection time, s | Real | Input | Not attribute | Constant | 10 |

| t1 | Acknowledge lack timeout, s | Real | Input | Not attribute | Constant | 1.5 |

| t2 | Acknowledge timeout, s | Real | Input | Not attribute | Constant | 1 |

| t3 | Test timeout, s | Real | Input | Not attribute | Constant | 2 |

| k | Maximum unconfirmed | Integer | Input | Not attribute | Constant | 12 |

| w | Maximum no ack | Integer | Input | Not attribute | Constant | 8 |

| itemsSet | Items set by: "ai|di|do:{IOA}[-{EndIOA}]:a[:{NameBase}]" | Text | Input | Full access | Variable | |

| items | All items | Object | Output | Full access | Variable | |

| this | Object | Object | Input | Not attribute | Variable | |

| f_frq | Function calculate frequency (Hz) | Real | Input | Not attribute | Variable | 1000 |

| f_start | Function start flag | Boolean | Input | Not attribute | Variable | 0 |

| f_stop | Function stop flag | Boolean | Input | Not attribute | Variable | 0 |

| f_err | Function error | String | Input | Not attribute | Variable | 0 |

- Create an output transport type "Sockets", set address to that like "Sockets.out_IEC60870", one for each the device-PLC.

- Set proper address and timeouts to the Sockets device-PLC.

- Create and start a logical controller object or use any present with need scheduling properties. For interaction by IEC-60870-104 you need set the execution period to no lesser then 100ms.

- Create a logical parameter object and select the template for that, one for each the devices-PLCs. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Transport — to the address of the transport into stage 1. Supported tracing for the hot change.

- Address — data address in format "{addr}.{OA}".

- Retry connection time — retry connection time in seconds at the connection lack.

- Acknowledge lack timeout, in seconds.

- Acknowledge timeout, in seconds.

- Test timeout, in seconds.

- Maximum unconfirmed — not used into the client but it is not generate like flow.

- Maximum no ack — maximum input packages after what the client will send "Ack".

- Result: The logical parameter object will perform interaction and place gathered data to the object "items", create/place and check to commands for proper attributes, created by the "itemsSet" instruction.

14. Mercury 200 (m200)

Description: One phase counter of electricity Mercury 200, 203.2Ò, 206 from firm Incotex (Author: Arsen Zakojan <

Version: 1.0

Output XML request structure of user protocol: <req first="255" second="16777215" data="{req}">{resp}</req>

req — request's data;

resp — respond's data;

first,second — first and three second bytes of the common address (0...4294967295).

Parameters of the template:resp — respond's data;

first,second — first and three second bytes of the common address (0...4294967295).

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| s | Energy from reset, tariffs sum | String | Input | Read only | Variable | |

| t1 | Energy from reset, tariff 1 | Real | Input | Read only | Variable | |

| t2 | Energy from reset, tariff 2 | Real | Input | Read only | Variable | |

| t3 | Energy from reset, tariff 3 | Real | Input | Read only | Variable | |

| t4 | Energy from reset, tariff 4 | Real | Input | Read only | Variable | |

| U | Voltage U(V) | Real | Input | Read only | Variable | |

| I | Current I(A) | Real | Input | Read only | Variable | |

| P | Power P(W) | Real | Input | Read only | Variable | |

| transport | Transport | String | Input | Not attribute | Constant | merc200 |

| netaddr | Network address | Real | Input | Not attribute | Constant | 1 |

| naladchik | Coded address by the program Fixer+ | Boolean | Input | Not attribute | Constant | 0 |

| tarif | Read energy from reset | Boolean | Input | Not attribute | Constant | 1 |

| UIP | Read current values | Boolean | Input | Not attribute | Constant | 1 |

| first | First byte of the address | Integer | Input | Not attribute | Variable | |

| second | Last 3 bytes of the address | Integer | Input | Not attribute | Variable | |

| f_stop | Function stop flag | Boolean | Input | Not attribute | Variable | 0 |

| f_err | Function error | String | Input | Not attribute | Variable | 0 |

| f_start | Function start flag | Boolean | Input | Not attribute | Variable | 0 |

| f_frq | Function calculate frequency (Hz) | Real | Input | Not attribute | Variable | 1000 |

- Create an output transport type "Serial" with name like to "merc200".

- Set proper address and timeouts for the Serial device.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create an object of the logical parameter and select the template for this, one for each device. Enable the parameter.

- Into tab "Template configuration" of the object of the logical parameter you need to set:

- Transport — to the address of the transport into stage 1.

- Network address — the counter's logical address.

- Coded address by the program Fixer+ — set the flag for counters coded by the program. Most likely the address will equal to apartment number.

- Read energy from reset — set the flag if you need the data.

- Read current values — set the flag to read current values.

- Result: The logical parameter object will perform interaction and place gathered data to the parameter attributes.

15. Mercury 230 (m230)

Description: Three phase counter of electricity Mercury 230, 231, 232, 233, 234, 236 from firm Incotex (Author: Arsen Zakojan <

Version: 1.0

Output XML request structure of user protocol: <req netaddr="255" data="{req}">{resp}</req>

req — request's data;

resp — respond's data;

netaddr — Network address. For counters Mercury 230, 231 and 233 the tree last digits are serial number or they are last two digits for the number more to 240. If the last numbers are zero, the network address is "1". Universal, broadcast address is "0".

Parameters of the template:resp — respond's data;

netaddr — Network address. For counters Mercury 230, 231 and 233 the tree last digits are serial number or they are last two digits for the number more to 240. If the last numbers are zero, the network address is "1". Universal, broadcast address is "0".

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| answer | Answer to the password request | String | Input | Read only | Variable | |

| TS | Read energy of tariffs sum | Boolean | Input | Not attribute | Constant | 0 |

| T1 | Read energy of tariff 1 | Boolean | Input | Not attribute | Constant | 0 |

| T2 | Read energy of tariff 2 | Boolean | Input | Not attribute | Constant | 0 |

| T3 | Read energy of tariff 3 | Boolean | Input | Not attribute | Constant | 0 |

| T4 | Read energy of tariff 4 | Boolean | Input | Not attribute | Constant | 0 |

| P | Read power P | Boolean | Input | Not attribute | Constant | 0 |

| Q | Read power Q | Boolean | Input | Not attribute | Constant | 0 |

| S | Read power S | Boolean | Input | Not attribute | Constant | 0 |

| U | Read voltage U | Boolean | Input | Not attribute | Constant | 0 |

| I | Read current I | Boolean | Input | Not attribute | Constant | 0 |

| K | Read power coefficient | Boolean | Input | Not attribute | Constant | 0 |

| F | Read frequency F | Boolean | Input | Not attribute | Constant | 0 |

| N | Read serial number | Boolean | Input | Not attribute | Constant | 0 |

| TSAp | Energy from resetting, tariffs sum A+ | Real | Input | Read only | Variable | |

| TSAm | Energy from resetting, tariffs sum A- | Real | Input | Read only | Variable | |

| TSRp | Energy from resetting, tariffs sum R+ | Real | Input | Read only | Variable | |

| TSRm | Energy from resetting, tariffs sum R- | Real | Input | Read only | Variable | |

| T1Ap | Energy from resetting, tariff 1 A+ | Real | Input | Read only | Variable | |

| T1Am | Energy from resetting, tariff 1 A- | Real | Input | Read only | Variable | |

| T1Rp | Energy from resetting, tariff 1 R+ | Real | Input | Read only | Variable | |

| T1Rm | Energy from resetting, tariff 1 R- | Real | Input | Read only | Variable | |

| T2Ap | Energy from resetting, tariff 2 A+ | Real | Input | Read only | Variable | |

| T2Am | Energy from resetting, tariff 2 A- | Real | Input | Read only | Variable | |

| T2Rp | Energy from resetting, tariff 2 R+ | Real | Input | Read only | Variable | |

| T2Rm | Energy from resetting, tariff 2 R- | Real | Input | Read only | Variable | |

| T3Ap | Energy from resetting, tariff 3 A+ | Real | Input | Read only | Variable | |

| T3Am | Energy from resetting, tariff 3 A- | Real | Input | Read only | Variable | |

| T3Rp | Energy from resetting, tariff 3 R+ | Real | Input | Read only | Variable | |

| T3Rm | Energy from resetting, tariff 3 R- | Real | Input | Read only | Variable | |

| T4Ap | Energy from resetting, tariff 4 A+ | Real | Input | Read only | Variable | |

| T4Am | Energy from resetting, tariff 4 A- | Real | Input | Read only | Variable | |

| T4Rp | Energy from resetting, tariff 4 R+ | Real | Input | Read only | Variable | |

| T4Rm | Energy from resetting, tariff 4 R- | Real | Input | Read only | Variable | |

| PS | Power P(W) by the phases sum | Real | Input | Read only | Variable | |

| P1 | Power P(W) by the phase 1 | Real | Input | Read only | Variable | |

| P2 | Power P(W) by the phase 2 | Real | Input | Read only | Variable | |

| P3 | Power P(W) by the phase 3 | Real | Input | Read only | Variable | |

| QS | Power Q(var) by the phases sum | Real | Input | Read only | Variable | |

| Q1 | Power Q(var) by the phase 1 | Real | Input | Read only | Variable | |

| Q2 | Power Q(var) by the phase 2 | Real | Input | Read only | Variable | |

| Q3 | Power Q(var) by the phase 3 | Real | Input | Read only | Variable | |

| SS | Power S(VA) by the phases sum | Real | Input | Read only | Variable | |

| S1 | Power S(VA) by the phase 1 | Real | Input | Read only | Variable | |

| S2 | Power S(VA) by the phase 2 | Real | Input | Read only | Variable | |

| S3 | Power S(VA) by the phase 3 | Real | Input | Read only | Variable | |

| U1 | Voltage U(V) by the phase 1 | Real | Input | Read only | Variable | |

| U2 | Voltage U(V) by the phase 2 | Real | Input | Read only | Variable | |

| U3 | Voltage U(V) by the phase 3 | Real | Input | Read only | Variable | |

| I1 | Current I(A) by the phase 1 | Real | Input | Read only | Variable | |

| I2 | Current I(A) by the phase 2 | Real | Input | Read only | Variable | |

| I3 | Current I(A) by the phase 3 | Real | Input | Read only | Variable | |

| KS | Power coefficient by the phases sum | Real | Input | Read only | Variable | |

| K1 | Power coefficient by the phase 1 | Real | Input | Read only | Variable | |

| K2 | Power coefficient by the phase 2 | Real | Input | Read only | Variable | |

| K3 | Power coefficient by the phase 3 | Real | Input | Read only | Variable | |

| F1 | Frequency F(Hz) | Real | Input | Read only | Variable | |

| N1 | Serial number | String | Input | Read only | Variable | |

| netaddr | Network address (0...240) | Integer | Input | Not attribute | Constant | 1 |

| password | Password | String | Input | Not attribute | Constant | 111111 |

| transport | Transport | String | Input | Not attribute | Constant | merc230 |

| f_stop | Function stop flag | Boolean | Input | Not attribute | Variable | 0 |

| f_err | Function error | String | Input | Not attribute | Variable | 0 |

| f_start | Function start flag | Boolean | Input | Not attribute | Variable | 0 |

| f_frq | Function calculate frequency (Hz) | Real | Input | Not attribute | Variable | 1000 |

- Create an output transport type "Serial" with name like to "merc230".

- Set proper address and timeouts for the Serial device.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create an object of the logical parameter and select the template for this, one for each device. Enable the parameter.

- Into tab "Template configuration" of the object of the logical parameter you need to set:

- Transport — to the address of the transport into stage 1.

- Network address (0...240) — logical address of the counter.

- Password — first level password, by default 111111.

- Set flags for all parameters you need to read.

- Result: The logical parameter object will perform interaction and place gathered data to the parameter attributes.

16. Shark Slave Communication Protocol (SSCP)

Description: Shark Slave Communication Protocol from EnergoCentrum PLUS, s.r.o.Author: Roman Savochenko <

Sponsored: Costumer Faster CZ (

Version: 0.6

Template parameters:

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport of the Ethernet network, Sockets | String | Input | Not attribute | Constant | SSCP |

| addr | Address [0...255] | Integer | Input | Not attribute | Constant | 1 |

| user | User | String | Input | Not attribute | Constant | admin |

| pass | Password | String | Input | Not attribute | Constant | rw |

| maxDtFrm | Maximum data frame size | Integer | Input | Not attribute | Constant | 2048 |

| listsDir | Folder of the list files | String | Input | Not attribute | Constant | SSCP |

| verPrt | Protocol version | Integer | Input | Read only | Variable | |

| maxDtFrmServ | Server's maximum data frame size Integer | Input | Read only | Variable | ||

| list | Variables selected for processing | Text | Input | Full access | Variable | |

| this | Object | Object | Input | Not attribute | Variable | |

- Create an output transport type "Sockets" like "SSCP", one for each the device.

- Set proper address to IP-address or host address of the remote device in the Ethernet network.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each the devices. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Transport — to the address of the transport into stage 1. Supported tracing for the hot change.

- Address — to the device's logical address in bus by upper transport.

- Result: The logical parameter object will perform:

- reading files of lists listsDir for creation and content forming of an attribute "selList" of list of all alowed device's attributes;

- reading of content of the attribute list of selected device's attributes to dynamic form their representing attributes into the parameter object;

- reading of the dynamic formed representing attributes;

- checking for changes and writing of the dynamic formed representing attributes.

17. Example: DCON (DCON)

Description: Mostly aimed for example implement the user protocols into OpenSCADA and contains only main functions into the protocol part.Author: Roman Savochenko <

Input user protocol's part: Test implements only processing for requests '#' and '@' with fixed reply data.

Using/configuring:

- Create an input transport type mostly "Serial" and set any ID.

- Set proper the address and the timeouts to the Serial device.

- Set transport protocol to "UserProtocol.DCON".

- Result: all requests to the input transports will process by input part of the module.

Output user protocol's XML request structure: <ReqSymb addr="1" err="1:Error">{req}</ReqSymb>

ReqSymb — request type symbol into the tag name, like: '#', '@', etc;

req — request/respond data;

addr — remote host address [1...240];

err — sets for the request result.

Using/configuring:req — request/respond data;

addr — remote host address [1...240];

err — sets for the request result.

- Create an output transport type "Serial" and set ID that like "DCON", one for each the devices' used serial bus.

- Set proper the address and the timeouts to the Serial device.

- Place some commands requests direct to present or new internal OpenSCADA procedures like:

- Result: Into variable data you will get the request's data part if no errors occur. The data is analog inputs' values.

18. Example: OWEN (OWEN)

Description: Mostly models ofAuthor: Constantine (IrmIngeneer)

Refactoring: Roman Savochenko <

Output user protocol's XML request structure: <mess addr="1" err="1:Error">{req}</mess> — message tag

req — request/respond data;

addr — remote station address (0...2047);

err — sets for the request result.

Using/configuring:addr — remote station address (0...2047);

err — sets for the request result.

- Create an output transport type "Serial" and set ID that like "OWEN", one for each the devices' used serial bus.

- Set proper the address and the timeouts to the Serial device.

- Place some commands requests direct to present or new internal OpenSCADA procedures like:

- Result: Into variable data you will get the request's data part if no errors occur.

19. One Wire by {DS9097,DS9097U} (1W_{DS9097,DS9097})

Description: One Wire sensors bus implementing by 1Wire-adapter {DS9097,DS9097U}. Supported direct and parasite powering for the temperature sensors.Supported 1Wire-devices: DS1820, DS1820/DS18S20/DS1920 (not tested), DS1822 (not tested), DS2413, DS2408, DS2450, DS2438.

Author: Roman Savochenko <

Version: 1.1, 1.1

Template parameters:

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport of the One Wire bus, Serial | String | Input | Not attribute | Constant | oneWire |

| tmResc | Rescan period, s | Real | Input | Not attribute | Constant | 60 |

| power | Power, for temperature | Boolean | Input | Read only | Variable | |

| this | Object | Object | Input | Not attribute | Variable | |

| f_frq | Function calculate frequency (Hz) | Real | Input | Not attribute | Variable | 1000 |

| f_start | Function start flag | Boolean | Input | Not attribute | Variable | 0 |

| f_stop | Function stop flag | Boolean | Input | Not attribute | Variable | 0 |

| f_err | Function error | String | Input | Not attribute | Variable | 0 |

- Create an output transport type "Serial", set address to that like "oneWire", one for each the One Wire bus.

- Set proper address, only for the adapter's serial device like "/dev/ttyS{N}". The serial port speed, asynchronous data format and timeouts will adjusted by the template.

- Create and start a logical controller object or use any present with the need scheduling properties.

- Create a logical parameter object and select the template for that, one for each One Wire bus. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- Transport of the One Wire bus, Serial — to the address of the transport into stage 1. Supported tracing for the hot change.

- Rescan period, s — periodicity of rescan to new and removed devices search.

- Result: The logical parameter object will perform at first searching to 1Wire devices on the bus and create included parameters to the each found one. Next the logical parameter object will perform gather data of the found devices and trace to modify of the writable device's properties.

20. I2C: PCF8591 (PCF8591)

Description: I2C 8-bit 4xA/D and D/A converter. Connect through a Serial output transport into the I2C mode.Author: Roman Savochenko <

Version: 1.0

Template parameters:

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport of the I2C, Serial | String | Input | Not attribute | Constant | i2c |

| addr | Device address [0...119] | Integer | Input | Not attribute | Constant | 72 |

| vRef | Reference voltage, V | Real | Input | Not attribute | Constant | 3.2 |

| ai0 | AI0 | Real | Input | Read only | Variable | |

| ai1 | AI1 | Real | Input | Read only | Variable | |

| ai2 | AI2 | Real | Input | Read only | Variable | |

| ai3 | AI3 | Real | Input | Read only | Variable | |

| ao | AO | Real | Input | Full access | Variable | |

| f_frq | Function calculate frequency (Hz) | Real | Input | Not attribute | Variable | 1000 |

| f_start | Function start flag | Boolean | Input | Not attribute | Variable | 0 |

| f_stop | Function stop flag | Boolean | Input | Not attribute | Variable | 0 |

| f_err | Function error | String | Input | Not attribute | Variable | 0 |

- Create an output transport type "Serial", set address to that like "i2c", one for each the I2C bus.

- Set proper address, only the I2C bus address like "/dev/i2c-{N}". Set the symbol's time into the timeouts field to minimum value.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each I2C slave device. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- transport — to the address of the transport into stage 1. Supported tracing for the hot change.

- addr — the I2C slave device's address [0...119].

- vRef — reference voltage of the AIs and AO.

- Result: The logical parameter object will perform interaction and place gathered data to the AI attributes and also will take the AO and write to the chip.

21. I2C: PCF8574 (PCF8574)

Description: I2C 8-bit 8DIO. Connect through a Serial output transport into the I2C mode.Author: Roman Savochenko <

Version: 1.0

Template parameters:

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport I2C | String | Input | Not attribute | Constant | i2c |

| addr | Device address (0, 119) | Integer | Input | Not attribute | Constant | 39 |

| di0 | DI0 | Boolean | Input | Read only | Variable | |

| di1 | DI1 | Boolean | Input | Read only | Variable | |

| di2 | DI2 | Boolean | Input | Read only | Variable | |

| di3 | DI3 | Boolean | Input | Read only | Variable | |

| di4 | DI4 | Boolean | Input | Read only | Variable | |

| di5 | DI5 | Boolean | Input | Read only | Variable | |

| di6 | DI6 | Boolean | Input | Read only | Variable | |

| di7 | DI7 | Boolean | Input | Read only | Variable | |

| do0 | DO0 | Boolean | Output | Full access | Variable | |

| do1 | DO1 | Boolean | Output | Full access | Variable | |

| do2 | DO2 | Boolean | Output | Full access | Variable | |

| do3 | DO3 | Boolean | Output | Full access | Variable | |

| do4 | DO4 | Boolean | Output | Full access | Variable | |

| do5 | DO5 | Boolean | Output | Full access | Variable | |

| do6 | DO6 | Boolean | Output | Full access | Variable | |

| do7 | DO7 | Boolean | Output | Full access | Variable | |

| f_frq | Function calculate frequency (Hz) | Real | Input | Not attribute | Variable | 1000 |

| f_start | Function start flag | Boolean | Input | Not attribute | Variable | 0 |

| f_stop | Function stop flag | Boolean | Input | Not attribute | Variable | 0 |

| f_err | Function error | String | Input | Not attribute | Variable | 0 |

- Create an output transport type "Serial", set address to that like "i2c", one for each the I2C bus.

- Set proper address, only the I2C bus address like "/dev/i2c-{N}". Set the symbol's time into the timeouts field to minimum value.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each I2C slave device. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- transport — to the address of the transport into stage 1. Supported tracing for the hot change.

- addr — the I2C slave device's address [0...119].

- Result: The logical parameter object will perform interaction and place gathered data to the DI attributes and also will take the DO and write to the chip.

22. I2C: BMP180 (BMP180)

Description: I2C Pressure and Temperature sensor. Connect through a Serial output transport into the I2C mode.Author: Roman Savochenko <

Version: 1.0

Template parameters:

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport of the I2C, Serial | String | Input | Not attribute | Constant | i2c |

| addr | Device address [0...119] | Integer | Input | Not attribute | Constant | 119 |

| oss | Oversampling setting (0...3) | Integer | Input | Not attribute | Constant | 0 |

| t | T, °Ñ | Real | Input | Read only | Variable | |

| p | P, Pa | Real | Input | Read only | Variable | |

| f_frq | Function calculate frequency (Hz) | Real | Input | Not attribute | Variable | 1000 |

| f_start | Function start flag | Boolean | Input | Not attribute | Variable | 0 |

| f_stop | Function stop flag | Boolean | Input | Not attribute | Variable | 0 |

| f_err | Function error | String | Input | Not attribute | Variable | 0 |

- Create an output transport type "Serial", set address to that like "i2c", one for each the I2C bus.

- Set proper address, only the I2C bus address like "/dev/i2c-{N}". Set the symbol's time into the timeouts field to minimum value.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each I2C slave device. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- transport — to the address of the transport into stage 1. Supported tracing for the hot change.

- addr — the I2C slave device's address [0...119].

- oss — oversampling setting of pressure measurement [0...3].

- Result: The logical parameter object will perform interaction and place gathered data to the Pressure and Temperature attributes.

23. I2C: DS3231 (DS3231)

Description: I2C RTC chip with Temperature sensor and calibration on it. Connect through a Serial output transport into the I2C mode.Author: Roman Savochenko <

Version: 1.0

Template parameters:

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport of the I2C, Serial | String | Input | Not attribute | Constant | i2c |

| addr | Device address [0...119] | Integer | Input | Not attribute | Constant | 119 |

| tm | Date and time, YYYY-MM-DDTHH:mm:SS | String | Input | Full access | Variable | |

| agOff | Aging offset, [-128...127] | Integer | Input | Full access | Variable | |

| t | T, °Ñ | Real | Input | Read only | Variable | |

| p32k | Enable 32768Hz | Boolean | Input | Full access | Variable | |

| pSQW | Enable SQUARE-WAVE OUTPUT | Boolean | Input | Full access | Variable | |

| pSQWf | SQUARE-WAVE OUTPUT frequency: 0-1Hz, 1-1.024kHz, 2-4.096kHz, 3-8.192kHz | Integer | Input | Full access | Variable | |

| f_frq | Function calculate frequency (Hz) | Real | Input | Not attribute | Variable | 1000 |

| f_start | Function start flag | Boolean | Input | Not attribute | Variable | 0 |

| f_stop | Function stop flag | Boolean | Input | Not attribute | Variable | 0 |

| f_err | Function error | String | Input | Not attribute | Variable | 0 |

- Create an output transport type "Serial", set address to that like "i2c", one for each the I2C bus.

- Set proper address, only the I2C bus address like "/dev/i2c-{N}". Set the symbol's time into the timeouts field to minimum value.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each I2C slave device. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- transport — to the address of the transport into stage 1. Supported tracing for the hot change.

- addr — the I2C slave device's address [0...119].

- Result: The logical parameter object will perform interaction and place gathered data to the DateTime, Temperature and some one state attributes and also will take the DateTime, some one state attributes and write it to the chip.

24. I2C: AT24C{32|64} (AT24CXX)

Description: Provides operations with EEPROM memory based on I2C chips AT24C32 (4KB) and AT24C64 (8KB). Supported random reading and writing.Author: Roman Savochenko <

Version: 1.0

Output user protocol's XML request structure: <{cmd} addr="{ChipAddr}" off="{MemOffset}" size="{ReadSize}" err="1:Error">{ReadWriteSeq}</{cmd}>

cmd — command, for now there allowed: "read", "write";

addr — I2C device address [0...119];

off — memory part offset;

size — readed memory block size.

ReadWriteSeq — Read/Write bytes sequence.

err — sets for the request result.

Using/configuring:addr — I2C device address [0...119];

off — memory part offset;

size — readed memory block size.

ReadWriteSeq — Read/Write bytes sequence.

err — sets for the request result.

- Create an output transport type "Serial", set address to that like "i2c", one for each the I2C bus.

- Set proper address, only the I2C bus address like "/dev/i2c-{N}". Set the symbol's time into the timeouts field to minimum value.

- Place some commands requests direct to present or new internal OpenSCADA procedures like:

- Result: Into text() for "read" you will get the read data if no errors occur.

25. GPIO: DHT11,22 (AM23XX) (DHT)

Description: Digital Temperature and Humidity Sensor for models: DHT11, DHT12, AM2302, AM2320, ... . The module designed for the sensors connect through GPIO, mostly it's Raspberry PI BCM2835 GPIO.Conditions: Exclusively realtime planing in the priority 199 (FIFO-99).

Author: Roman Savochenko <

Version: 1.0

Template parameters:

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| addr | GPIO address with functions mode(), get() and put(), mostly it's BCM2835 | String | Input | Not attribute | Constant | DAQ.BCM2835.pi.pi |

| pin | IO pin number of the GPIO | Integer | Input | Not attribute | Constant | 17 |

| tries | Tries [1...5] | Integer | Input | Not attribute | Constant | 2 |

| dev | Device (0-DHT11, 1-DHT22) | Integer | Input | Not attribute | Constant | 1 |

| t | T, °Ñ | Real | Input | Read only | Variable | |

| h | H, % | Real | Input | Read only | Variable | |

| f_frq | Function calculate frequency (Hz) | Real | Input | Not attribute | Variable | 1000 |

| f_start | Function start flag | Boolean | Input | Not attribute | Variable | 0 |

| f_stop | Function stop flag | Boolean | Input | Not attribute | Variable | 0 |

| f_err | Function error | String | Input | Not attribute | Variable | 0 |

- Create an output controller and parameter object in DAQ module "BCM 2835", by default it's "pi.pi".

- Create and start a logical controller object or use any present with need scheduling properties (FIFO-199).

- Create a logical parameter object and select the template for that, one for each sensor. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- addr — To the address of the "BCM 2835" parameter like "DAQ.BCM2835.pi.pi". Supported tracing for the hot change.

- pin — GPIO pin number where connected the data pin of the sensor.

- tries — Tries of the sensor read.

- dev — Generic device specific selection.

- Result: The logical parameter object will perform interaction and place gathered data to the Temperature and Humidity attributes.

26. GPIO|I2C: 1602A(HD44780) (1602A)

Description: LCD Module 1602A, STN, BLUB, 16 Character x 2 Line, 5 x 8 Dots, by the direct (Raspberry PI BCM2835 GPIO) or I2C (PCF8574) wiring.Conditions: Default planing policy but realtime one preferred.

Author: Roman Savochenko <

Version: 1.1

Template parameters:

| ID | Parameter | Type | Mode | Attribute | Configure | Value |

| transport | Transport of the I2C, Serial (i2c) or GPIO address with function put(), mostly it's BCM2835 (DAQ.BCM2835.pi.pi) | String | Input | Not attribute | Constant | i2c |

| addr | I2C device address [0...119] | Integer | Input | Not attribute | Constant | 39 |

| RS | GPIO Pin: Reset | Integer | Input | Not attribute | Constant | 7 |

| E | GPIO Pin: Enable | Integer | Input | Not attribute | Constant | 8 |

| D4 | GPIO Pin: Data4 | Integer | Input | Not attribute | Constant | 25 |

| D5 | GPIO Pin: Data5 | Integer | Input | Not attribute | Constant | 24 |

| D6 | GPIO Pin: Data6 | Integer | Input | Not attribute | Constant | 23 |

| D7 | GPIO Pin: Data7 | Integer | Input | Not attribute | Constant | 18 |

| ln1 | Line 1 | String | Input | Full access | Variable | |

| ln2 | Line 2 | String | Input | Full access | Variable | |

| f_frq | Function calculate frequency (Hz) | Real | Input | Not attribute | Variable | 1000 |

| f_start | Function start flag | Boolean | Input | Not attribute | Variable | 0 |

| f_stop | Function stop flag | Boolean | Input | Not attribute | Variable | 0 |

| f_err | Function error | String | Input | Not attribute | Variable | 0 |

- Create an output controller and object of parameter in DAQ module "BCM 2835", by default it's "pi.pi" or create an output transport type "Serial", set address to that like "i2c", one for each the I2C bus.

- Create and start a logical controller object or use any present with need scheduling properties.

- Create a logical parameter object and select the template for that, one for each display. Enable the parameter.

- Into tab "Template configuration" of the logical parameter object you need set:

- transport — To the address of the "BCM 2835" parameter like "DAQ.BCM2835.pi.pi" or to the address of the transport into stage 1. Supported tracing for the hot change.

- addr — The I2C slave device's address [0...119].

- RS, E, D4, D5, D6, D7 — GPIO pins number where connected proper data ones of the sensor.

- Result: The logical parameter object will perform interaction and set lines' values to the display.